Background & Challenge

In high-voltage power transmission systems, circuit breaker contacts are critical components. Conventional W-Cu contacts suffer from low density, weak arc erosion resistance, and susceptibility to welding failure under extreme conditions.

Technical Breakthrough: Vertical Sintering Infiltration

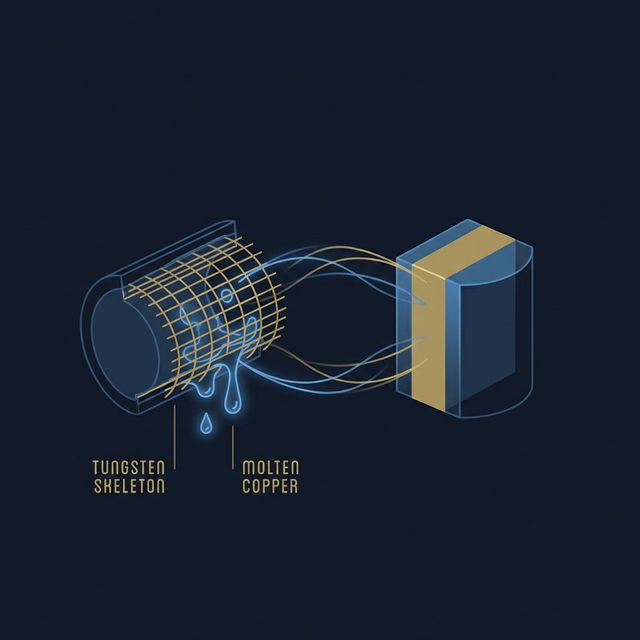

Prof. Chen invented a novel "Vertical Sintering Infiltration" process that uses the synergistic effect of gravity and capillary forces to uniformly infiltrate molten copper into a porous tungsten skeleton.

- Densification: Eliminates porosity defects inherent in conventional cold-press sintering

- Integral forming: Achieves one-piece joining of contact material and conductive rod, eliminating secondary brazing

- Impact: Products are used at scale in domestic high-voltage circuit breakers, winning the National Sci-Tech Progress Award (2nd Class)

Representative Achievements

- [Commercialized Patent] Method for preparing integral high-voltage electrical contacts by vertical sintering infiltration

- [Review Paper] Recent progress in development of tungsten-copper composites: Fabrication, modification and applications. Int. J. Refractory Metals and Hard Materials, 2018

CPC Layered Composites

Building on the high-temperature sintering infiltration technology, the group developed Cu/MoCu/Cu (CPC) layered composites for thermal management packaging in high-power electronic devices:

- Process innovation: Integral high-temperature infiltration sintering of Cu and MoCu, achieving metallurgical bonding at the interface

- Structural design: CPC laminated structures fabricated into composite plates via rolling

- Industry collaboration: Joint project with Jinduicheng Molybdenum Co., supported by the Xi'an Hard-Tech Innovation Program

- IP portfolio: 2 national invention patents granted